When you think about industries currently being revolutionized by technology, the construction industry might not be the first one that comes to mind. Once thought of as an industry that was slow to embrace technology, the majority of the construction industry is beginning to embrace new technological advances and the benefits they bring. These technology advances allow construction crews to work safer, inspectors to view hard-to-reach areas with ease, and customers to experience projects in virtual reality, long before the project is complete. In this article, we’ll explore the many ways technology is impacting the construction industry, and what it means for builders, suppliers, and customers.

Attack of the drones

No, they haven’t become sentient; but they are “attacking” the construction industry and changing the way we do business. Despite the government’s recent regulations, drones remain as popular as ever. Popularized in other industries such as the military, the price of drones has dropped significantly over the past few years, making it more affordable for other industries to put them to use. For example, the DJI Phantom 3 Professional with built-in 4K video capabilities can be purchased for around $1,100.00. The decrease in cost, coupled with the increase in possible uses, has led to drones being found around construction sites to assist with the following:

- Drones are being used to survey potential construction sites with minimal disruption to the existing structure or land.

- Inspectors use drones to perform inspection work in hard-to-reach places or places with limited access.

- Despite being in the early stages of feasibility, drones may be used to actually create or put together structures. Recently, researchers in Zurich used drones to construct a rope bridge, capable of supporting a human.

- Government agencies now use drones to check for construction violations or safety code violations.

Affordable drones, such as the DJI Phantom 3 Professional seen here, have helped revolutionize the construction industry with their ability to capture high-quality video and stream it to multiple devices.

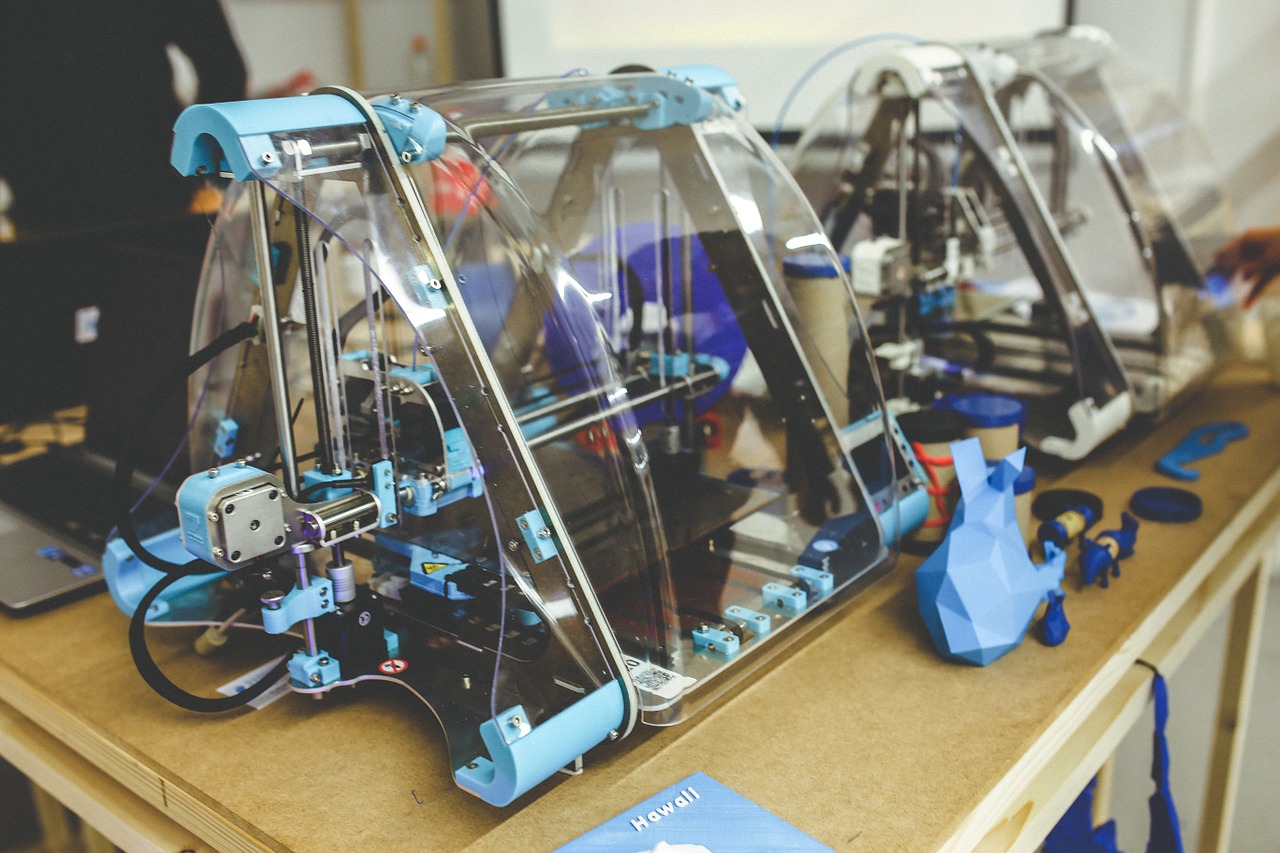

Everybody was 3-D Printing

The healthcare industry truly pioneered 3-D printing technology, spurring it’s own sub-industry called 3D bioprinting. The healthcare industry has already used 3-D bioprinting in the creation and transplantation of several tissues including skin, bone, vascular grafts, and more. The applications of 3-D printing to the construction industry seem limitless, and the industry has begun to implement it to benefit from cost savings and higher efficiencies in the construction process. 3-D printing will also be used to:

- Create detailed 3-D models of potential construction projects to show prospective customers before breaking ground.

- Reduce the amount of time spent planning and sequencing complex assemblies from weeks to hours. This will translate into shorter schedules and cost savings for the builder and consumer.

- Solve homelessness. While certainly optimistic, the speed and efficiency with which 3-D printers operate could be used to help combat the homelessness in an inexpensive, eco-friendly way.

3-D printing machines may revolutionize the construction industry by reducing the amount of time required to procure building materials.

Reality has become virtual

In the construction industry, making changes once construction is underway can cost customers time and money. With the increase in popularity and adoption of virtual reality technology, changes can be reviewed virtually before being requested, resulting in cost savings and preventing project timelines from getting off track. Virtual reality is also improving collaboration internally, as various members of the same construction team can see and visualize the finished product as well as any changes that need to be implemented.

Virtual reality headsets, such as the one seen above, will allow prospective home buyers to take a virtual tour of their home before construction starts.

Connecting you and the Internet of Things

The Internet of Things (IoT) is a simple name for a complex concept. The IoT is a network of physical objects, devices, vehicles, buildings, and other items that are embedded with electronics, software, and sensors, and are also connected to a network to collect and exchange data with other physical objects.

Imagine driving home from work on a freezing January day. As you approach your house, your car sends a signal to the thermostat in your house to begin warming the house to an acceptable level. You see, when you left for work in the morning, the GPS in your phone told the thermostat in your house that you were gone. To save money, the amount of energy used on heating the home was reduced throughout the day until you were close to home again that evening. These interconnected devices, all collecting and sharing information, make up the IoT.

While there are many possible uses for IoT in the construction industry, reducing cost and worker safety have been two primary focuses as the technology solutions are developed and implemented.

- By utilizing advanced sensors on costly equipment, machinery can self-detect the impending need for a repair before the machine completely breaks, often leading to a smaller repair bill.

- GPS tracking devices placed on expensive tools and equipment can help prevent theft and save money by reducing the need to purchase costly replacements.

- Wearable technology for workers can monitor vital signs and the type of motions workers are making to ensure safe construction practices are being followed.

- A supply chain connected to the IoT allows suppliers and construction companies to better coordinate the ordering and supply of inventory to prevent project delays and help reduce cost.

Feeling the embrace

As the construction industry embraces technology, it should fundamentally change the way we do business in a positive way. Inefficiencies in processes can be identified and eliminated and time spent making costly changes or fixing mistakes can be reduced drastically. The speed with which residential homes and commercial buildings can be built will be increased, while technology will assure they are just as safe, if not safer, than they are today.

For more valuable tips on how to turn your home into a smart home without breaking the bank, check out our previous article "How to turn your house into a smart home for less than $1,000."